What if I told you that Chick-fil-A’s supply chain has faced some serious hiccups, from ingredient shortages to supplier delays? And yet, through it all, they’ve managed to keep customers happy (well, mostly).

Ever hit up Chick-fil-A craving that perfect chicken sandwich, only to find out they’re running low on chicken or, even worse, your favorite sauce? Total buzzkill, right?

You’d think a fast-food giant like Chick-fil-A has it all figured out, but even they’ve had some pretty wild supply chain nightmares.

But here’s the thing—no matter what gets thrown at them, Chick-fil-A always seems to come up with some clever workaround. Whether it’s switching up suppliers last minute, tweaking their menu, or putting limits on their beloved sauces (RIP unlimited Chick-fil-A Sauce), they’ve learned to roll with the punches.

As small business owners, there’s a lot to learn from how they tackle these roadblocks.

So, let me show you some of Chick-fil-A’s supply chain messes and how they manage to keep customers coming back for more. Trust me, there’s some gold in here for anyone running a business!

Chick-fil-A is all about that fresh, high-quality goodness, but lately, their supply chain has been more wobbly than a chicken on a tightrope. Supplier delays and ingredient shortages have been throwing a bit of a tantrum, threatening to mess with their smooth operations.

Let’s start with the star of the show—chicken. When your entire brand is built on selling chicken sandwiches, running low on chicken isn’t just an inconvenience—it’s a full-blown crisis. Without a reliable supply of high-quality chicken, Chick-fil-A had to consider limiting portions, putting pressure on both suppliers and restaurant operations.

Back in 2021, Chick-fil-A found itself in a bit of a pickle (or maybe a nugget?), dealing with a chicken shortage that had some locations clucking in panic. Customers wanted their spicy chicken sandwiches, but the chickens? They were playing hard to get.

So, what caused this poultry predicament? It was the perfect storm of supply chain chaos:

As if the chicken shortage wasn’t enough, Chick-fil-A had another disaster on their hands – a sauce shortage! For many loyal fans, the sauce is life. So when they started running out, it was basically a national emergency.

On May 4, 2021, Chick-fil-A had to come clean on their website: “Due to industrywide supply chain shortages, some items, like sauces, may be unavailable.” Cue the collective gasp of horror from customers everywhere.

To manage the chaos, Chick-fil-A limited customers to one sauce packet per entrée, two per meal, and three for a 30-count nugget order. This rationing was not uniformly applied across all locations initially but reflected local responses to the shortages.

So, what caused this saucy situation?

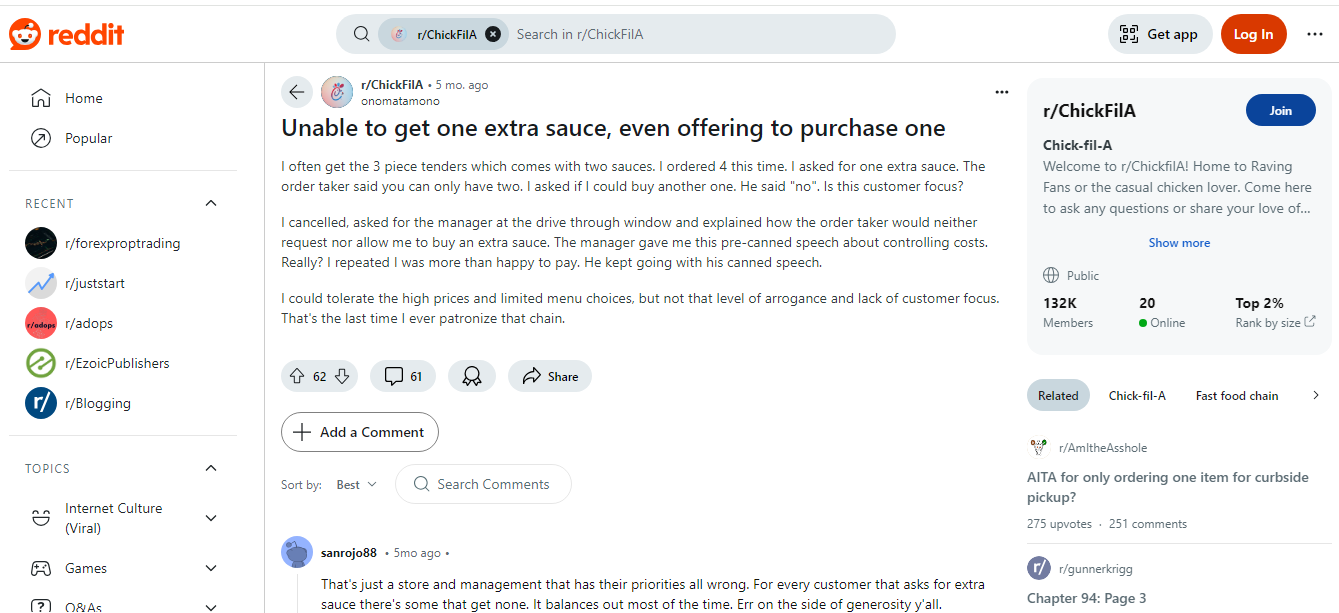

Naturally, Chick-fil-A fans were not pleased. For many, the sauce is as important as the sandwich itself. You can’t just dip your nuggets in thin air! The lack of sauce led to some serious disappointment, proving once and for all that you just can’t mess with people’s Chick-fil-A sauce and expect them to stay calm.

The limitations imposed on sauce distribution have sparked frustration among regular customers who enjoy multiple sauces with their meals.

Source:https://www.reddit.com/r/ChickFilA/comments/1c8d4yx/unable_to_get_one_extra_sauce_even_offering_to/

🚨 LET’S TAKE A BREAK FROM THE SAUCE FOR A SECOND, SHALL WE? 🚨

Thank you.

I want to quickly give you my 8D Framework To Launch Your Business eBook. It’s a step-by-step guide designed to help you build your product, launch it perfectly, and continue scaling it as much as you want.

If you’re starting a new business, you’ll find tremendous value inside, trust me. You could do much worse things with your time then to check it out here:

Back to Chick-fil-A…

When Chick-fil-A found itself in the middle of a chicken crisis, they didn’t just throw in the towel (or the napkins). Nope, they rolled up their sleeves and made some clever moves to keep the nuggets coming. Here’s how they tackled the great chicken shortage of 2021:

In an effort to keep the chicken supply flowing, Chick-fil-A decided to tweak their antibiotics policy. They shifted from their strict “No Antibiotics Ever” (NAE) rule to a slightly more flexible “No Antibiotics Important to Human Medicine” (NAIHM) policy.

Translation? They can use some antibiotics that don’t matter much for humans, helping them navigate the chicken shortage while still keeping things pretty responsible in the health department. It’s like bending the rules, but for a good cause—so we all get to keep munching on those crispy nuggets.

Chick-fil-A learned a valuable lesson: relying on just a couple of suppliers is like putting all your eggs in one basket. When those suppliers were hit with labor shortages and production hiccups, Chick-fil-A was left scrambling.

So, they decided to cast a wider net and started working with more poultry suppliers—both locally and nationally—kind of like building a backup chicken squad.

They partnered with more regional and national suppliers, like McLane Company, whose distribution centers were total rock stars during the crisis. One center in Riverside, California, was especially on point, boasting over 97% on-time delivery and nearly 100% fill rates. That’s some serious chicken power.

Chick-fil-A also opened new distribution centers in Olathe, Kansas, and Maryland Heights, Missouri. These spots weren’t just random picks—they were strategically placed to help local suppliers and make sure the chicken was always flowing, especially when the big national suppliers hit a snag.

The Olathe center, for example, now helps serve multiple restaurants in the Kansas City area, keeping them stocked and ready for hungry customers.

By partnering with regional suppliers, they were able to bypass some of the larger bottlenecks in the national supply chain without needing to vertically integrate by owning farms or production facilities.

These smaller suppliers were less affected by the broader disruptions and could deliver more consistently. It’s like expanding your friend group so you always have someone to bail you out!

Chick-fil-A realized that their usual just-in-time inventory model wasn’t cutting it during a crisis, so they beefed up (well, chickened up?) their inventory game. They invested in more storage space to stockpile chicken and other essentials.

Think of it as their emergency chicken stash, ready to keep things running smoothly even when the supply chain goes wonky. More storage, fewer empty fryers—everyone wins.

Chick-fil-A also focused on optimizing its menu during the chicken shortage by temporarily limiting more complex or less popular menu items such as:

These adjustments allowed Chick-fil-A to manage its chicken supply effectively while still meeting customer demand for its most popular products.

When Chick-fil-A ran into a sauce shortage (gasp!), they had to make some tough calls. Chick-fil-A announced that it would limit the number of sauce cups given to customers. Specifically, they are now providing one sauce per entrée, two sauces per meal, and three sauces for a 30-count nugget order.

This adjustment aims to ensure that all customers can still enjoy their meals while managing limited stock.

As a quick fix, Chick-fil-A encouraged customers to grab bottled versions of their most popular sauces at the grocery store. It’s like saying, “Hey, why not take the sauce home with you?” This not only helped ease the shortage of those tiny packets but also gave bottled sauce sales a nice little boost. Now you can slather sauce on everything you eat at home—fries, burgers, maybe even salads (no judgment here).

Chick-fil-A wasn’t shy about the whole sauce shortage drama. They put up signs in stores and sent out messages through their mobile app to keep everyone in the loop. By being upfront about the situation and explaining what they were doing to fix it, they dodged a lot of potential customer rage.

Their honesty helped manage expectations, and most folks appreciated that Chick-fil-A wasn’t just hiding behind a curtain while their sauce supply dwindled.

Chick-fil-A isn’t just about delicious chicken sandwiches anymore. They’ve had to keep up with the ever-changing preferences of their customers, which means their supply chain has been on its toes more than ever. Let’s take a look at how they’re dealing with the latest trends, from health nuts to fast-lane diners.

Once upon a time, fast food was all about “fried, tasty, and cheap.” Now? People are all about grilled chicken, salads, and whatever’s trending in the health world.

Chick-fil-A’s signature fried chicken? Still a hit, but they’ve had to roll out the red carpet for leaner meats, fresher veggies, and things like gluten-free options.

Of course, all these healthy demands meant more than just tossing some lettuce on the menu. Chick-fil-A had to level up their supply chain game—sourcing cleaner ingredients (like the “no artificial preservatives” kind) and finding suppliers who could keep up with all the kale and quinoa needs of today’s health-conscious diners. And yeah, it got a little tricky, but hey, that’s the cost of making fast food a bit fancier.

Gone are the days when people would casually wait in line for their food. Now it’s all about speed—whether it’s grabbing something on the go or ordering via app while barely looking up from your phone.

The pandemic accelerated this trend, with more people opting for takeout, curbside pickup, and third-party delivery services.

Chick-fil-A had to crank up the pace of their supply chain to make sure their crispy sandwiches and fresh salads didn’t get stuck in traffic (or the back of a delivery truck). Because nothing says “customer meltdown” like waiting too long for your chicken.

People these days want options. They want to swap sauces, get grilled chicken instead of fried, throw in extra veggies, or maybe skip the bun entirely. And of course, Chick-fil-A said, “Sure, why not?”—but their supply chain probably had a mini freakout.

More customization means stocking all sorts of extra ingredients at every location. That’s not just a few extra sauce packets—think veggies, sauces, and proteins all perfectly prepped and ready to go for whatever wild combinations customers dream up.

And somehow, Chick-fil-A’s still cranking out orders fast enough to keep us all happy.

The company responded to these changing consumer preferences by implementing several key strategies across its supply chain.

To meet the demand for healthier options, Chick-fil-A expanded its menu with a variety of lighter, nutritious choices, including:

In response to consumer demand for convenience, Chick-fil-A ramped up its investment in technology and streamlined its supply chain to support various dining options:

These days, everyone’s talking about sustainability and ethical sourcing like it’s the hottest new trend in town—people want to know where their food comes from and if it’s been sourced responsibly.

Chick-fil-A’s been getting the memo and is tackling everything from chicken ethics to eco-friendly packaging. Here’s how they’re handling the pressure to be greener than their logo.

Consumers now expect companies, including Chick-fil-A, to utilize responsibly sourced ingredients. This includes:

With these demands, Chick-fil-A has had to rethink its sourcing and distribution methods. Sure, committing to ethical sourcing makes them look good, but it also complicates things and can jack up costs.

Chick-fil-A decided to go antibiotic-free with their chicken since 2019, which is great for ethical reasons but means they’re sourcing from a smaller pool of farmers. It’s like trying to find a needle in a haystack while also making sure that needle is ethically sourced!

This shift illustrates how ethical considerations can complicate supply chains and increase costs—an important lesson for entrepreneurs as they evaluate their own sourcing practices.

Recently, Chick-fil-A had to tweak its “no antibiotics” policy to “No Antibiotics Important To Human Medicine” (NAIHM). This means they can use some antibiotics for animal health that aren’t crucial for humans.

It’s like saying, “We’re still keeping it clean, but we need a little wiggle room here!”

This change shows how fast-food chains are juggling high-quality standards with the chaos of their supply chains.

Chick-fil-A is committed to sourcing poultry that is antibiotic-free and raised under humane conditions. The company collaborates with suppliers who share its sustainability goals, requiring careful vetting of new suppliers to ensure a consistent supply of ethically sourced products.

Starting in the spring of 2024, Chick-fil-A has been serving chicken raised without antibiotics that are important for human health. This policy aims to reduce antibiotic resistance while ensuring the quality of the meat served.

Chick-fil-A also conducts regular third-party audits of its suppliers to verify compliance with these standards and maintains an Animal Wellbeing Council that includes external experts who provide feedback on the company’s practices and policies.

The company has begun transitioning to eco-friendly packaging solutions by moving away from Styrofoam cups and other non-recyclable materials.

Chick-fil-A now uses biodegradable or recycled materials for packaging, necessitating close coordination with suppliers to maintain quality and availability.

In May 2023, the brand introduced a recyclable double-wall paper cup to replace PET plastic cups and single-wall paper cups. The new cup offered the advantage of keeping drinks chilled for a longer period. It is also made from paper which is sourced from certified sustainably managed forests (SFI).

Chick-fil-A has invested in initiatives aimed at reducing food waste throughout its supply chain and restaurant operations. Surplus food from specific locations is donated to local food banks, while food scraps are repurposed for composting or animal feed.

For example, one of the standout technologies employed by Chick-fil-A is the ORCA™ aerobic food waste digester. This system utilizes a natural biological process to convert food waste into a liquid that is safe for municipal wastewater treatment facilities.

The ORCA digester incorporates air, water, and microbiology to break down food scraps, creating no solid byproduct and eliminating the need for additional handling or costly hauling services.

This method significantly reduces carbon emissions associated with traditional waste disposal methods, such as garbage trucks.

Participating Chick-fil-A Owner-Operators have reported substantial success with this technology. For example, one restaurant diverted over 3.1 tons of food waste from landfills within less than a year of installing the ORCA digester.

This innovative approach is part of Chick-fil-A’s broader goal to divert over 25 million pounds of food waste from landfills by 2025, showcasing their commitment to environmental stewardship and sustainability.

The company has also established the Chick-fil-A Shared Table program, which aims to donate surplus food to local organizations, including food shelters and soup kitchens.

Since its inception in 2012, this program has successfully donated over 23 million meals to those in need across various communities. By redirecting surplus food away from landfills, Chick-fil-A not only addresses food insecurity but also reduces overall waste.

Chick-fil-A’s even figured out how to turn used cooking oil into renewable diesel fuel. Yep, that frying oil you thought was just for waffle fries is now helping power the future.

Thanks to their partnership with Darling Ingredients, over 1,000 restaurants are now recycling their oil for cleaner fuel. Who knew your nugget order could be saving the planet?

These waste reduction efforts not only help Chick-fil-A meet its sustainability goals but also contribute to cost management, as diverting waste can lead to lower operational costs in the long run.

Chick-fil-A aims to divert 25 million pounds of food waste from landfills by 2025 through various programs like the Chick-fil-A Shared Table program and composting initiatives.

The company’s Global Impact Report highlights these ambitious goals alongside its dedication to community engagement and environmental stewardship.

Email subscription is available ONLY TODAY (oh, okay, and tomorrow).

Surely, we respect your inbox! Unsubscription works every day.

We’d love to tailor your experience — which of these best describes you?